Tag: track

Massive Track Project

In 2022 I was commissioned to build a number of O scale track components for another modeler. The total project…

Back in Business

1 It’s been a real long time. I spent the summer focused on 1:1 trains and couldn’t find the…

Hard Times for Hand Laying

Hard Times for Hand Laying I’ve hand laid a 3′ section around a 24″ radius corner. There are some minor…

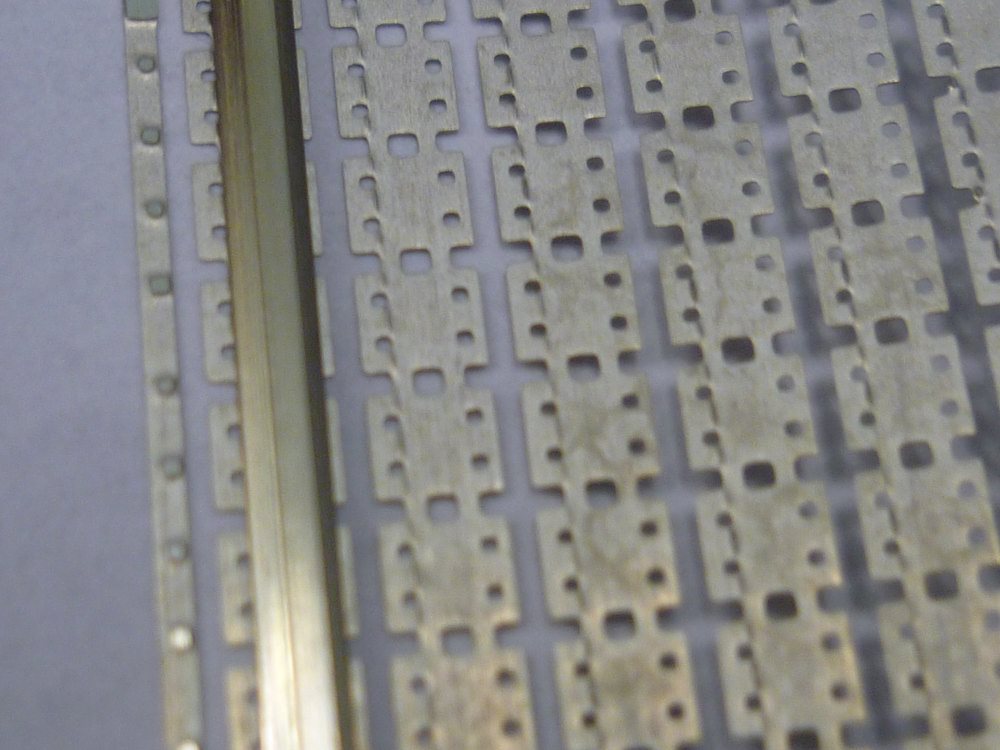

Tie Plate News

. Cosmetic Tie Plates I received the Proto 87 Stores cosmetic tie plates this afternoon. I was hoping to use…

Sleight of Hand

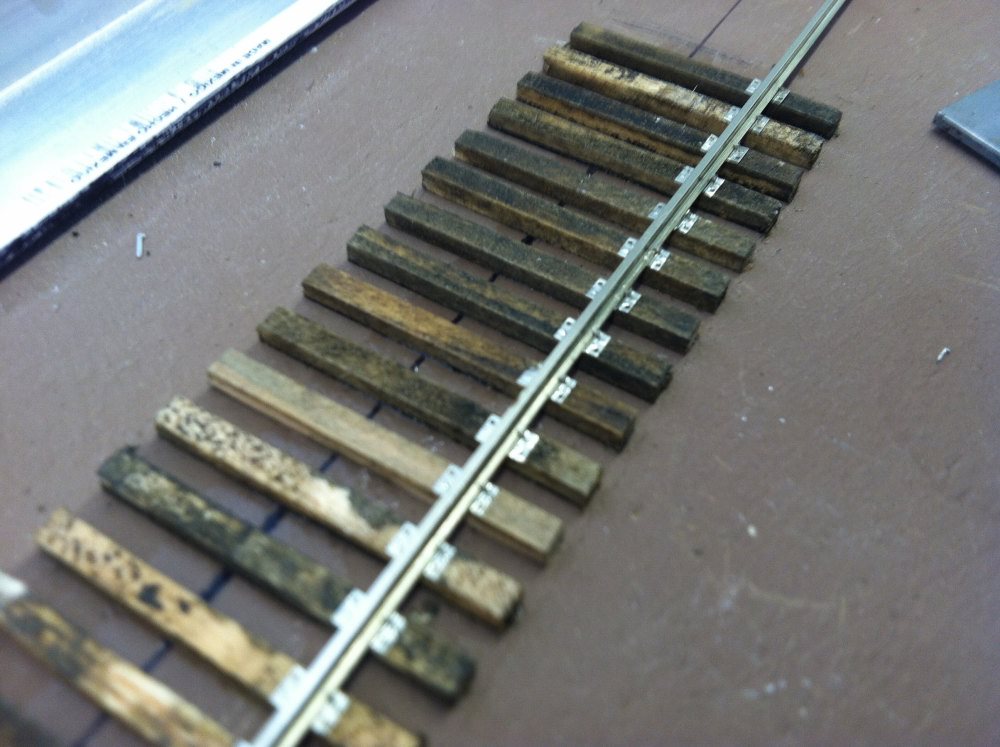

A break from building turnouts I decided to try something more relaxing: hand laying track. Why did I think this…

Finishing & Staining Wood Ties – Video

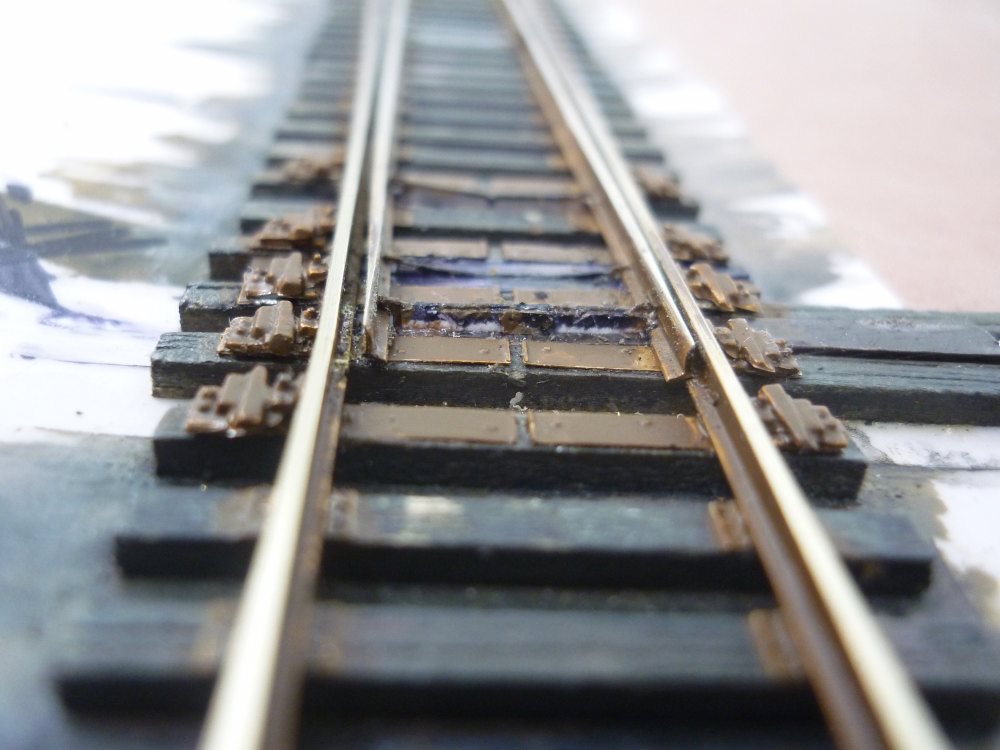

Finishing & Staining Wood Ties I’ve already glued my ties to the roadbed. I used Kappler 8′ 6″ wood cross…

Tie Coloring – Humbrol #98

I’ve tried a new two step method to staining my ties. Paint the ties with Humbrol #98 Enamel Paint. It’s…

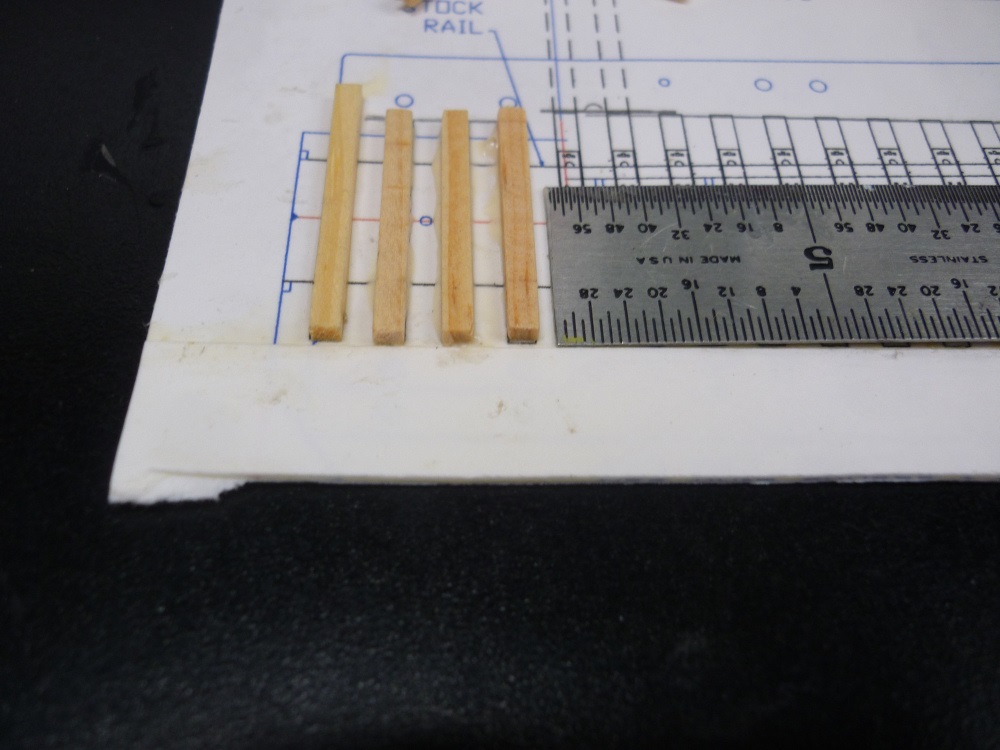

Templates Have Instructions Too

I’ve been wanting to try making a turnout without using the Proto:87 Stores Switch-Works Ultimate Turnout jigs. I’ve seen many…

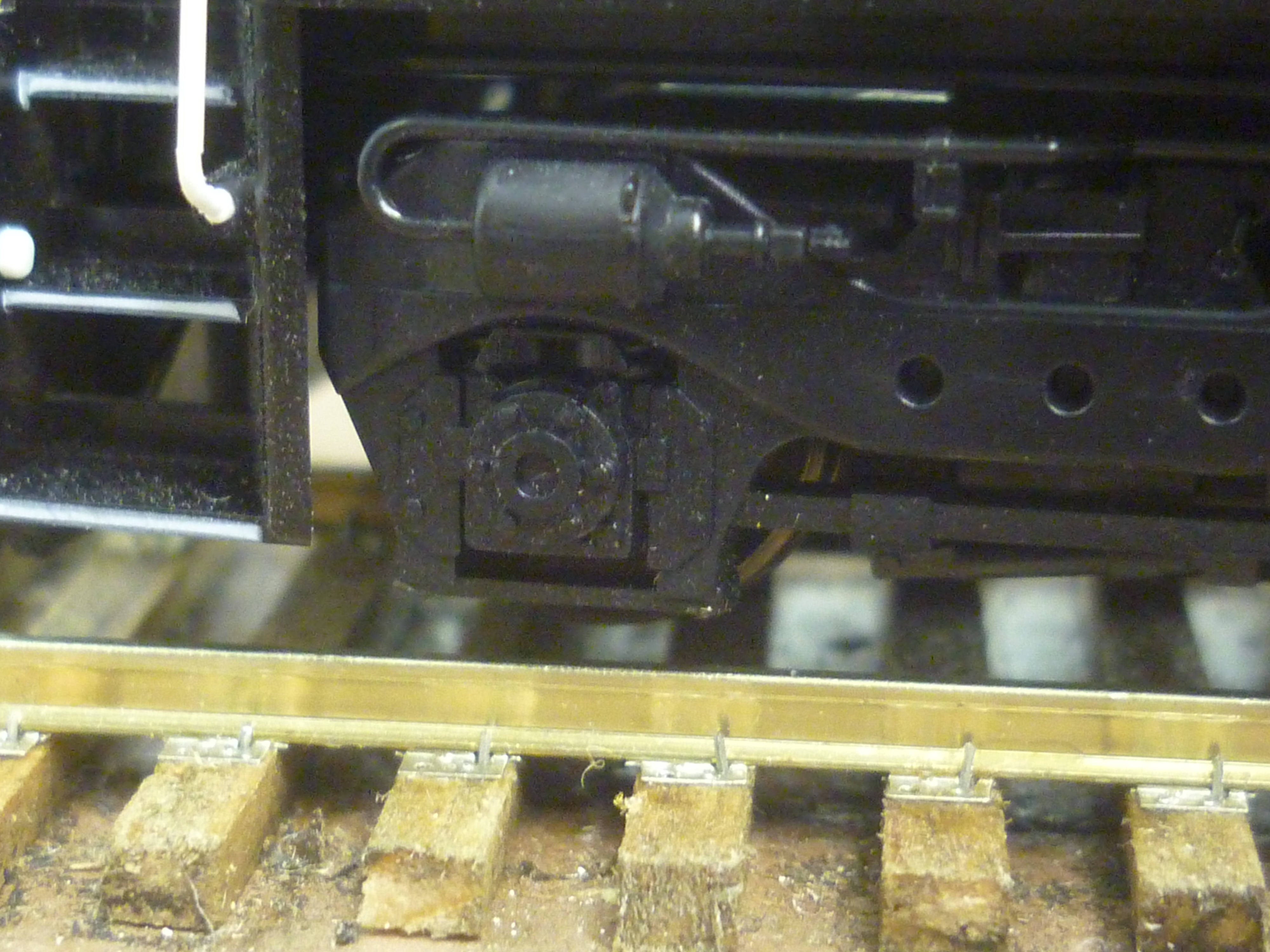

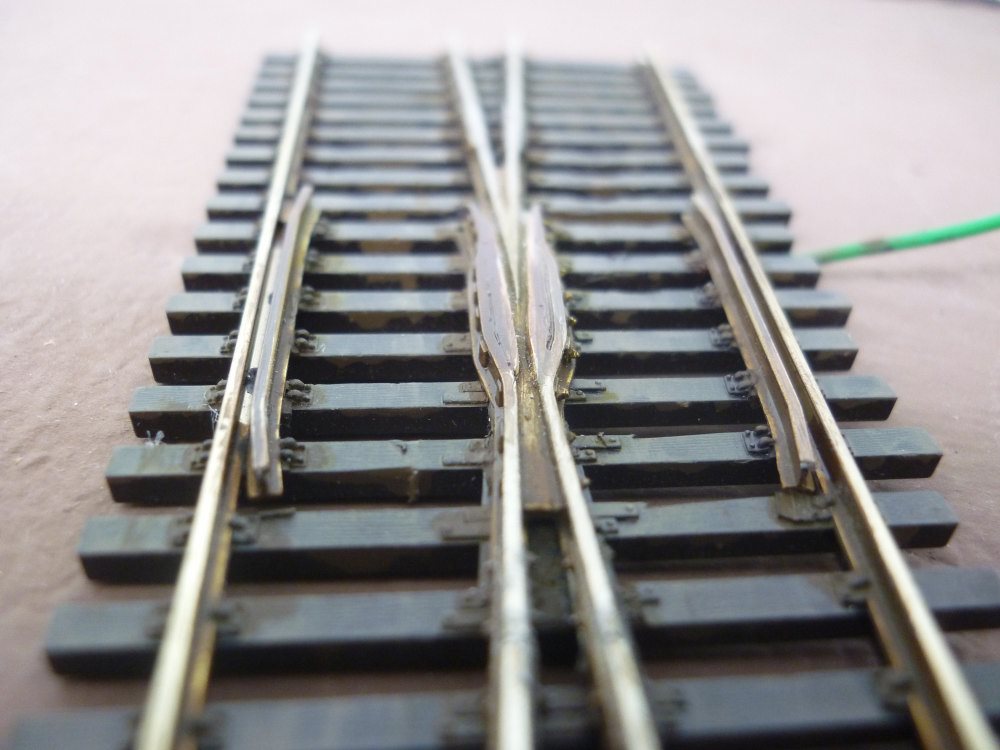

Peco Proto:87 Conversion (or Diversion)

A long time ago, I purchased a stash of Peco #8 turnouts, just in case I got fed up…

Another Turnout And I’m Still Learning

What little time I had this summer for model railroading was pretty much devoted to making another Proto:87 Stores #10…