Tag: frame

Drawers and Lower Fascia

Lower Fascia I started installing the lower 1/8″ hardboard fascia. I had it cut into 6 1/2″ strips at Home Depot,…

Skyboards, workbench and valance fascia

I tacked in 13″ hardboard skyboards around the layout. I’ll be painting these Polar White. I cut painted and installed…

West Valance and Desk Complete

West Valance I completed the west valance. Mostly:) It still needs a little touch up paint. The valance fascia is…

Desks, Decks and a Beautiful Skyboard

I added the keyboard tray to the bottom of the desk. Everything fits! Yeah! I still need to cut some…

Time for a New Desk

When I built my Halland Yard layout, I decided to build my office desk into the closet. It was primarily…

Finishing the Main Deck

I was able finish up cutting the main deck. I cut a filler piece for the east wall, filled a…

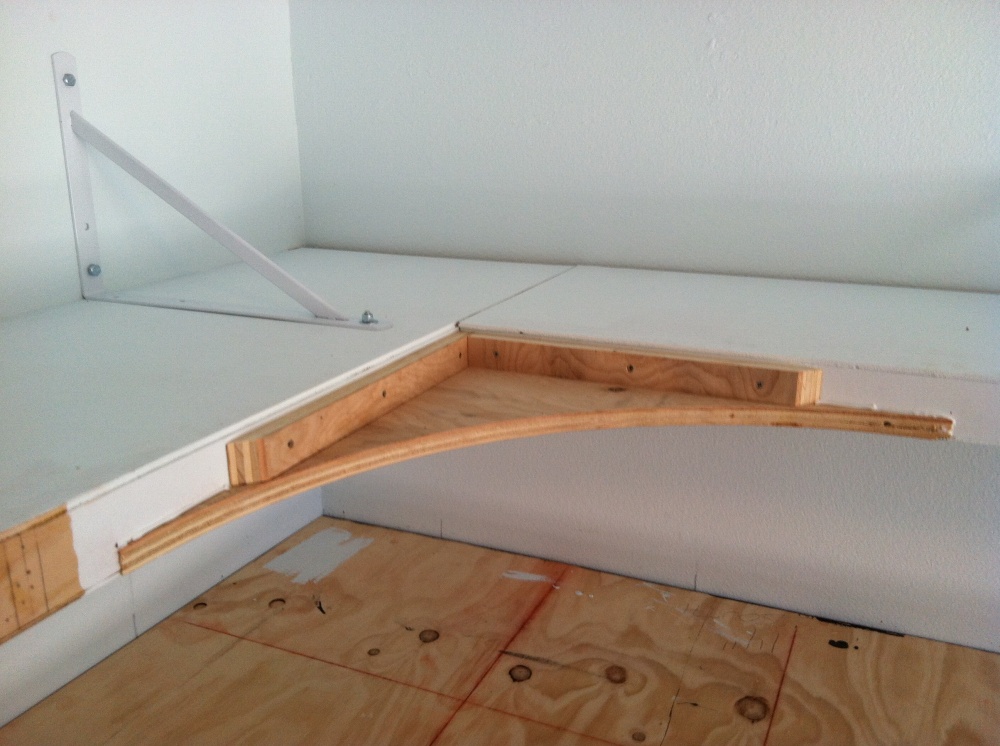

Valance Brackets

I painted the top and underside of the valance Polar White. Then installed the triangle brackets that provide the permanent…

Benchwork Continues – Into the Closet

More benchwork today. I started with a tricky section that would be the sub-roadbed where the main layout enters the…

Touch up and Valance 4-16-2012

A couple extra hours of work allowed me to do a little touch up and finish out the valance frame….

Construction Marathon 4-15-2012

A nice day and generous parents led me to a construction marathon this afternoon. I spent a total of 8…