Tag: shelf layout

Touch up and Valance 4-16-2012

April 16, 2012

A couple extra hours of work allowed me to do a little touch up and finish out the valance frame….

Construction Marathon 4-15-2012

April 15, 2012

A nice day and generous parents led me to a construction marathon this afternoon. I spent a total of 8…

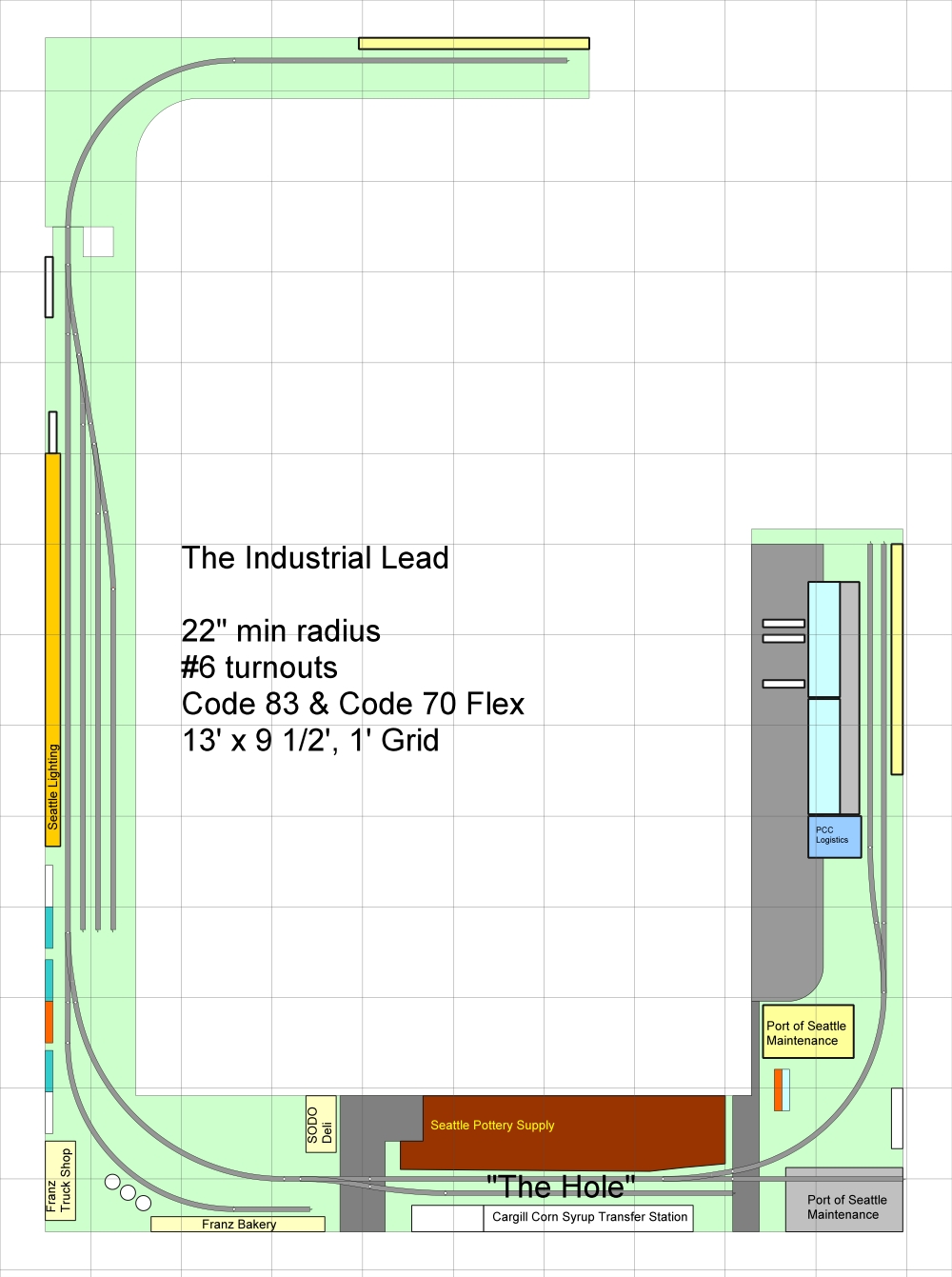

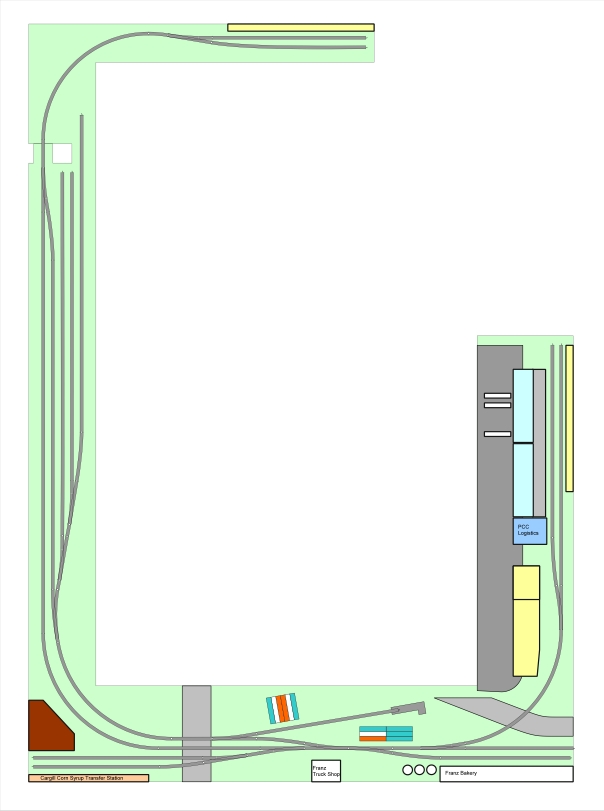

Track Plan – 01

January 5, 2012

Track Plan Updates I’ve decided to eliminate the runaround and go with a more prototypical track arrangement. Especially “The Hole”.I’ve…

The Industiral Lead – Introduction

January 5, 2012

I am designing a modern day HO industrial layout. The layout is inspired by my experiences railroading in Seattle. It…