Tag: proto:87

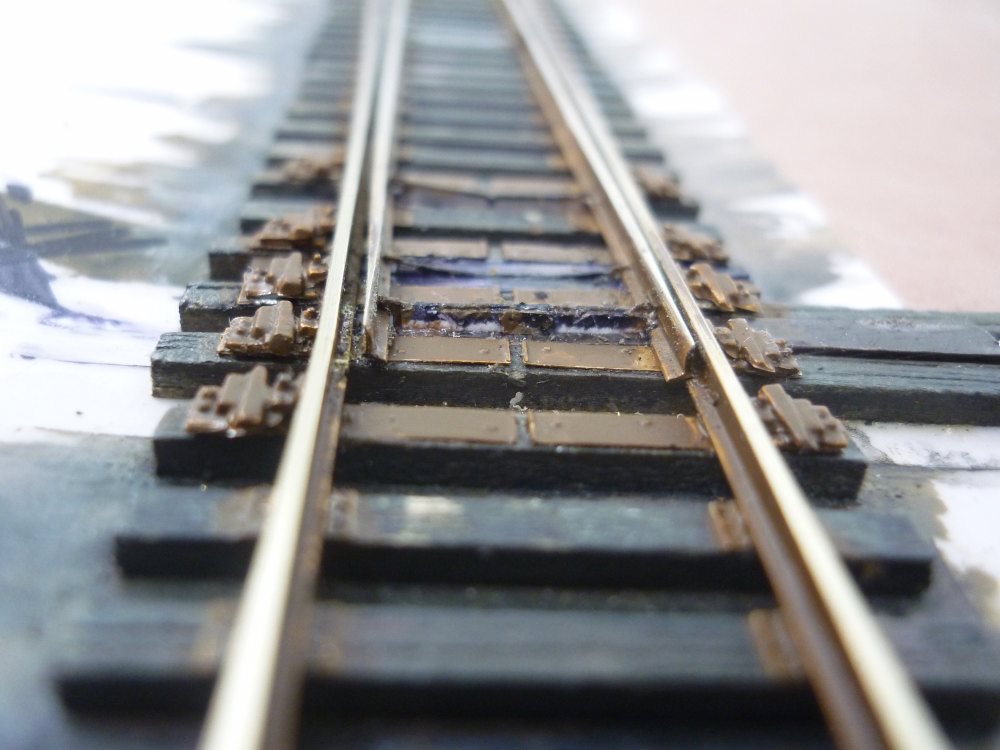

Hard Times for Hand Laying

Hard Times for Hand Laying I’ve hand laid a 3′ section around a 24″ radius corner. There are some minor…

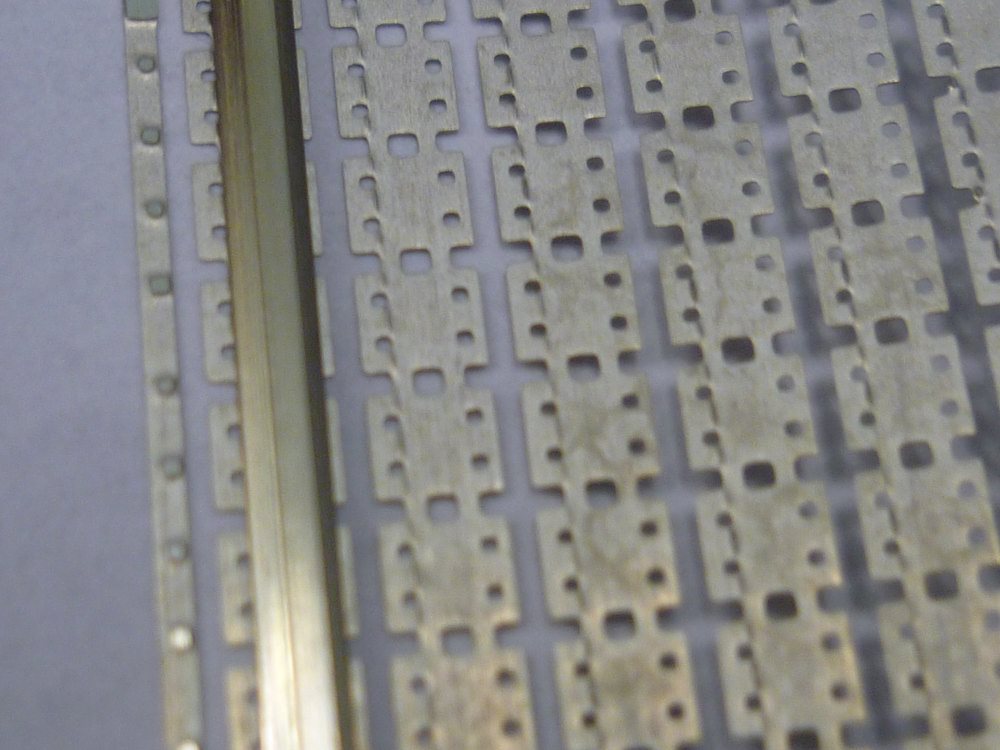

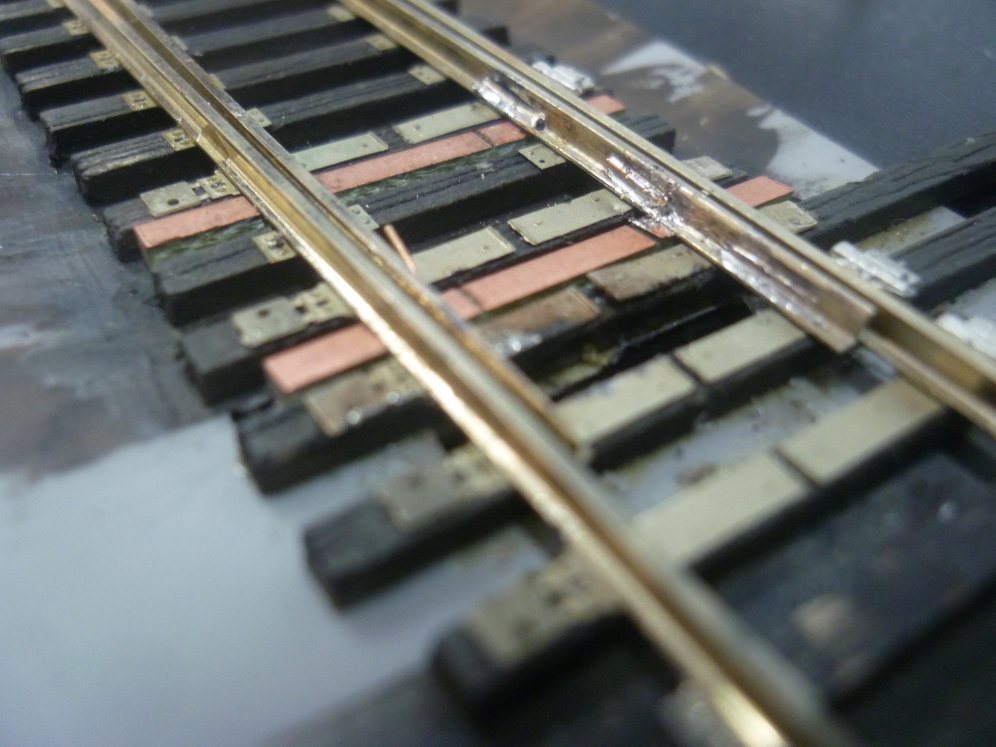

Tie Plate News

. Cosmetic Tie Plates I received the Proto 87 Stores cosmetic tie plates this afternoon. I was hoping to use…

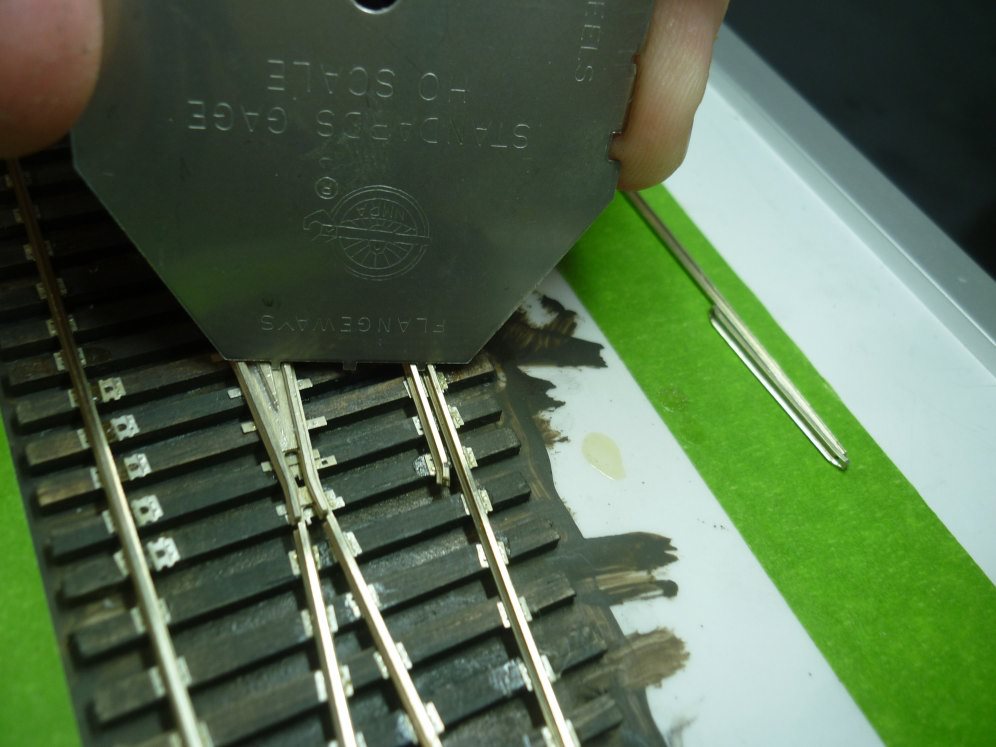

Templates Have Instructions Too

I’ve been wanting to try making a turnout without using the Proto:87 Stores Switch-Works Ultimate Turnout jigs. I’ve seen many…

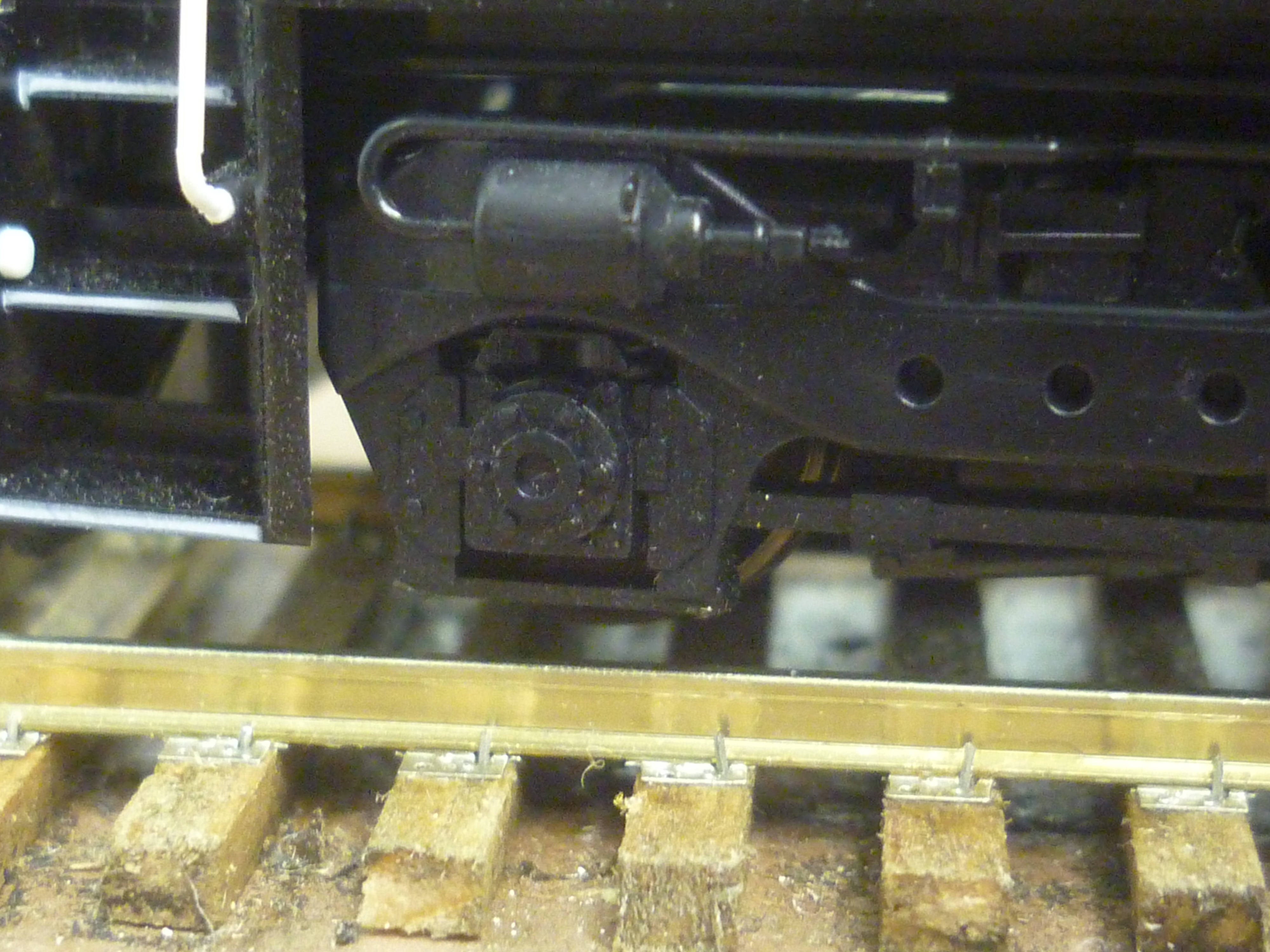

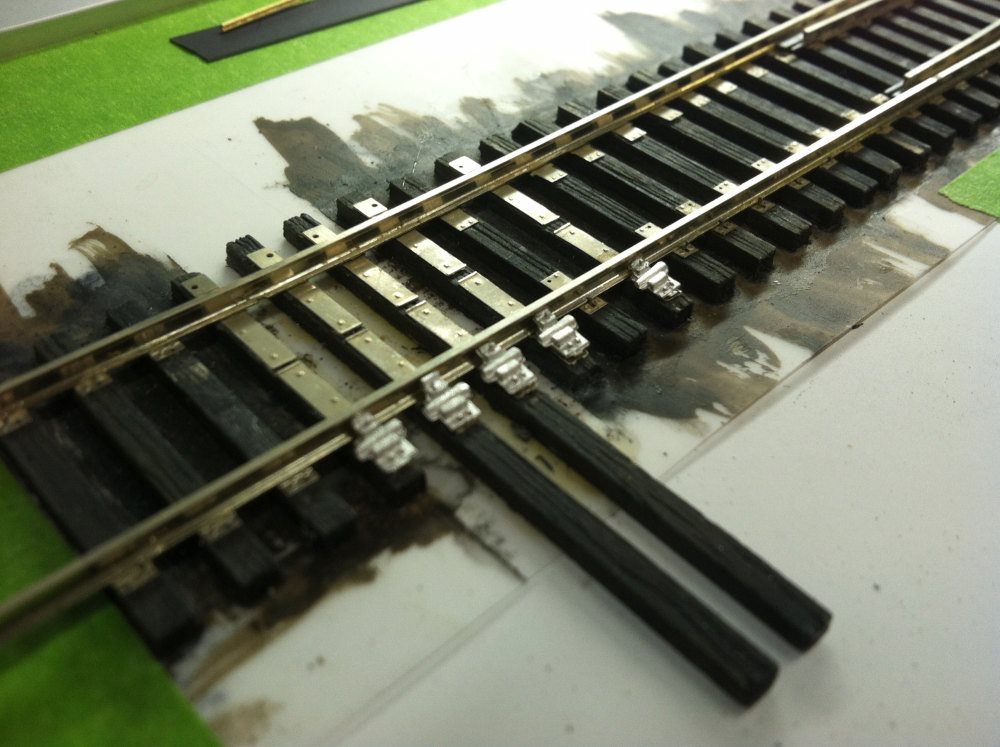

Peco Proto:87 Conversion (or Diversion)

A long time ago, I purchased a stash of Peco #8 turnouts, just in case I got fed up…

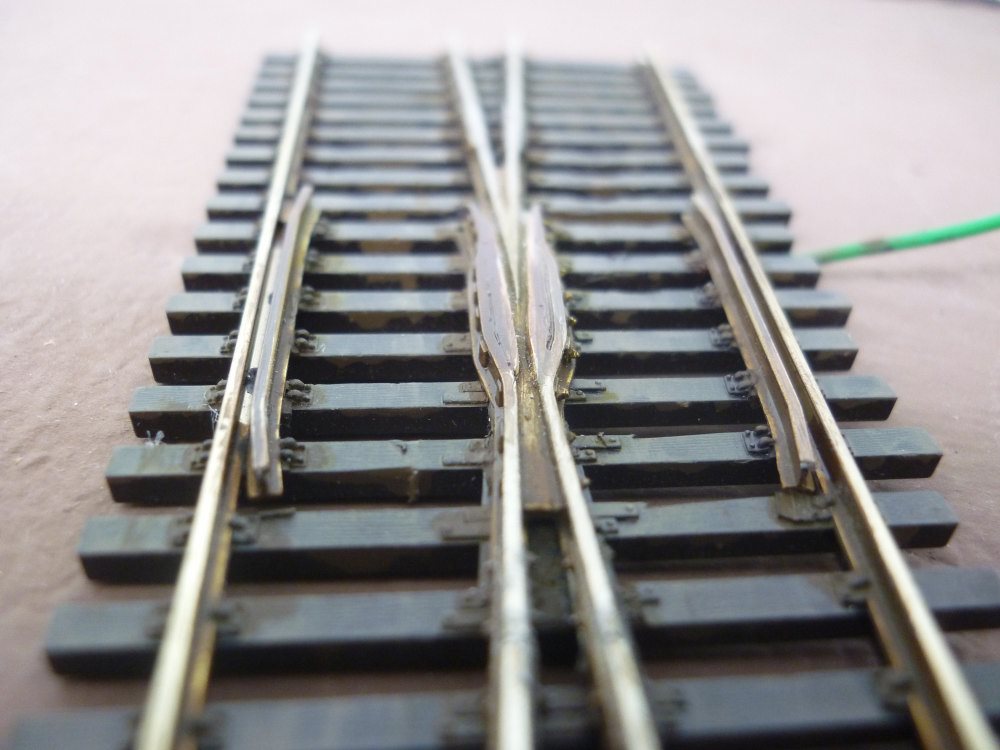

Another Turnout And I’m Still Learning

What little time I had this summer for model railroading was pretty much devoted to making another Proto:87 Stores #10…

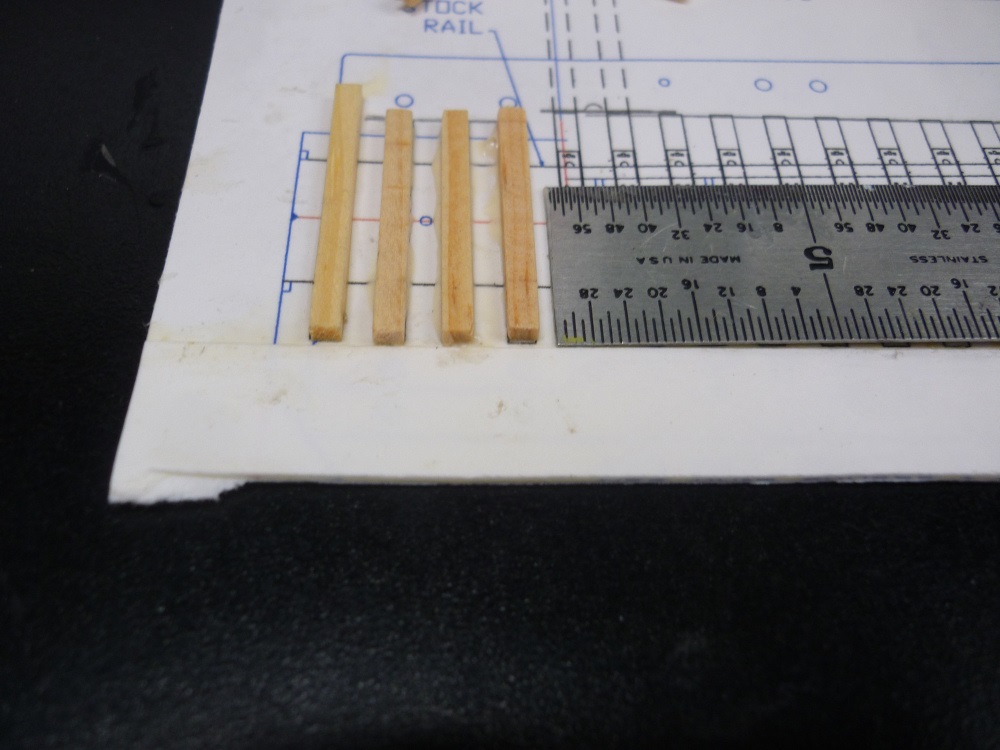

Throw Bar Throw Down

— Shimming Proto:87 Stores “Ultimate” Throw Bars I’m continuing to build Proto:87 Stores “Ultimate” turnouts. One feature I’ve complained about before is holding…

Summer Spurt 2013

It’s been a real slow summer. No time for trains. Kids summer camp brought me a couple of hours of…

Switch-Works Points

This video shows how to install points for the Switch-Works “Ultimate” turnout. Switch-Works is a set of jigs for assembling…

Switch-Works Guard Rails

This video shows how to lay guard rails for the Switch-Works “Ultimate” turnout. Switch-Works is a set of jigs for assembling…

“Ultimate” Turnout Clinic

Thank you to everyone that attended Build the “Ultimate” Turnout Clinic. As promised, I’ve posted an abbreviated version of…