Tag: peco

How Deep is Your Flange?

October 19, 2014

I spent a good portion of my modeling time this summer modifying and super-detailing three Peco turnouts. I replaced the…

Peco Proto:87 Conversion (or Diversion)

September 1, 2013

A long time ago, I purchased a stash of Peco #8 turnouts, just in case I got fed up…

Frog Survey

October 30, 2012

Being a locomotive engineer, I look at turonouts every day. And the model turnouts always look toy like. I’ve never…

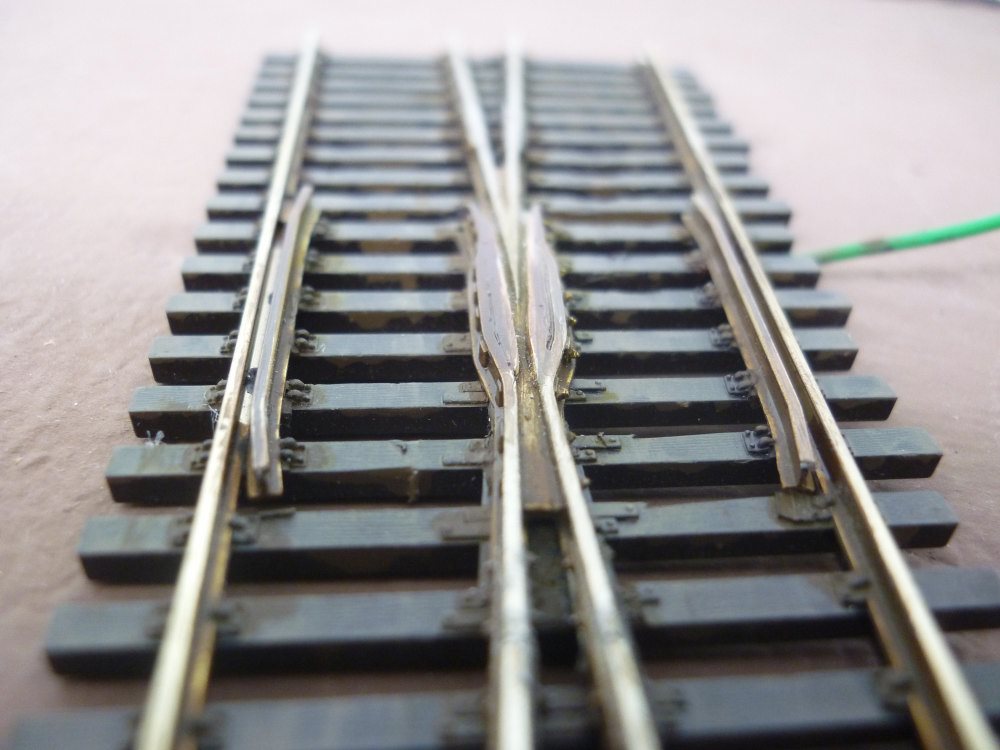

Peco Headblock Swap

October 23, 2012

Swapping Headblock ties on Peco Code 83 turnouts. Peco Code 83 turnouts come with the headblock ties extending off of…

Expanding Test Track

September 29, 2012

I’ve now got two test tracks: A Peco Code 83 Track, which I installed previously, but have now expanded. A…