Tag: switch-works

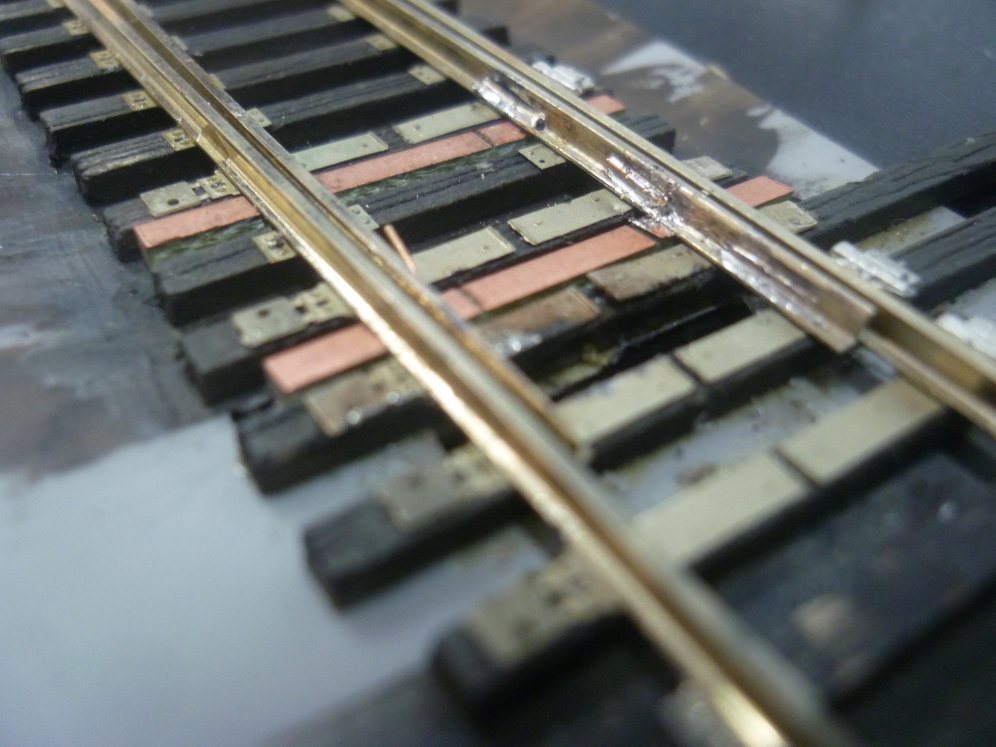

Throw Bar Throw Down

— Shimming Proto:87 Stores “Ultimate” Throw Bars I’m continuing to build Proto:87 Stores “Ultimate” turnouts. One feature I’ve complained about before is holding…

Summer Spurt 2013

It’s been a real slow summer. No time for trains. Kids summer camp brought me a couple of hours of…

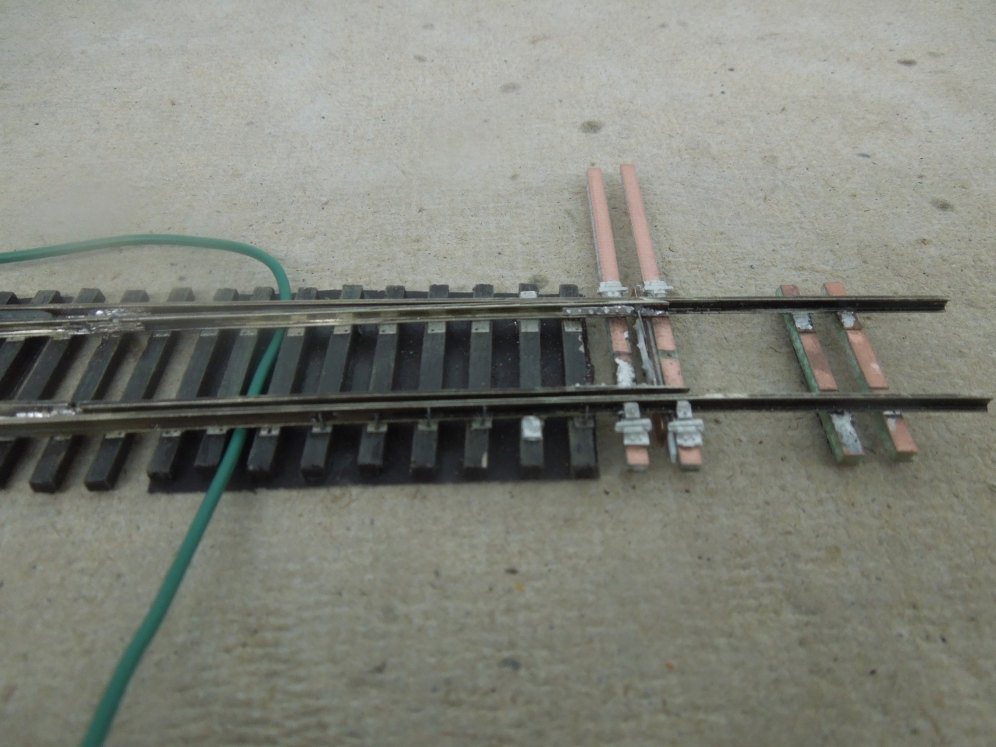

Switch-Works – A Second Turnout

February has been a hard month and my second turnout project has been stalled by parts delays, illness, a death,…

Switch-Works Lessons Learned

I’ve finished assembling my first Proto:87 turnout using the Switch-Works Turnout Building fixture. It took about a month and I…

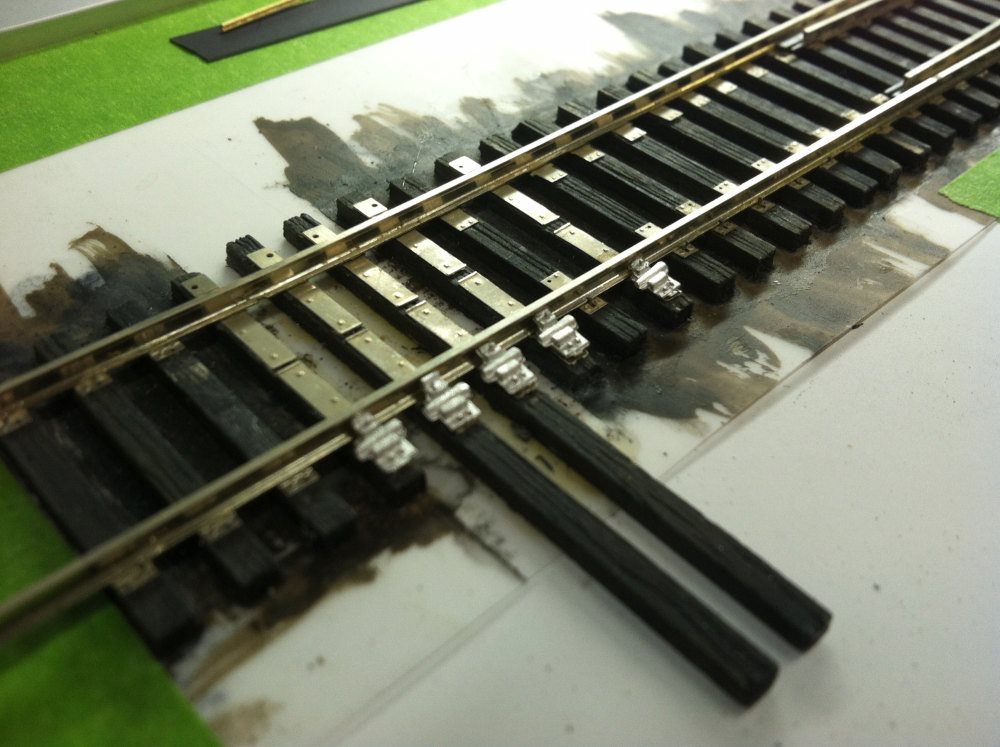

Switch-Works Take 2

I am building a #10 turnout with Proto:87 Stores Switch-Works assembly fixture. I thought I’d be clever and use Press-N-Seal…

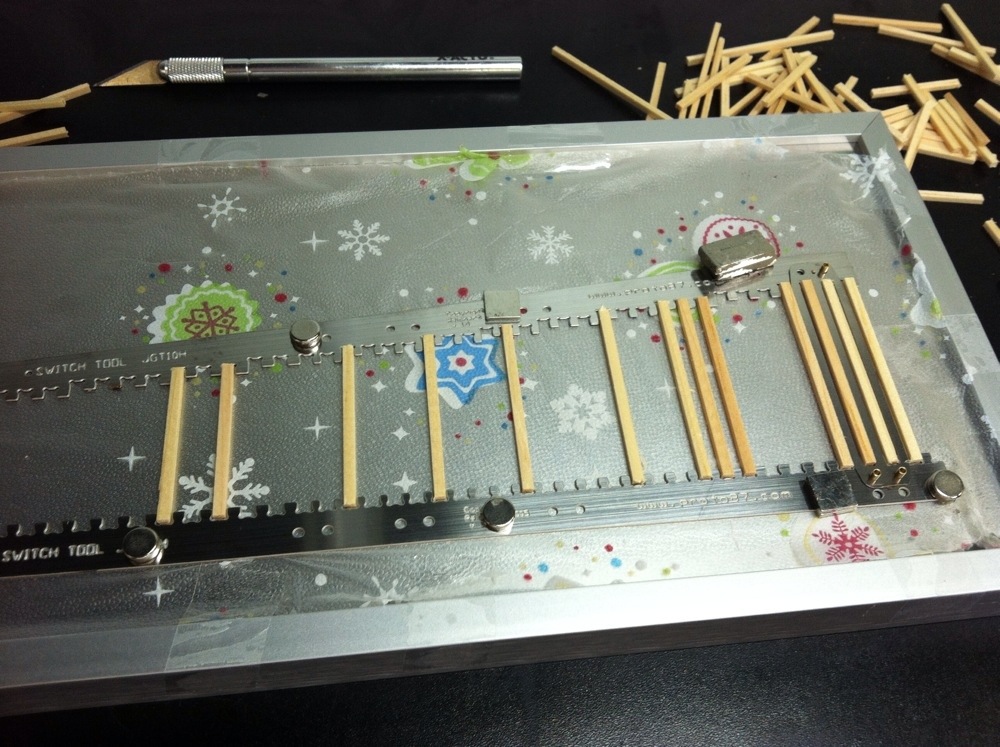

Switch-Works Arrives

My Switch-Works assembly fixture arrived recently and I finally got a chance to get started building some #10 turnouts. After…