Tag: turnout

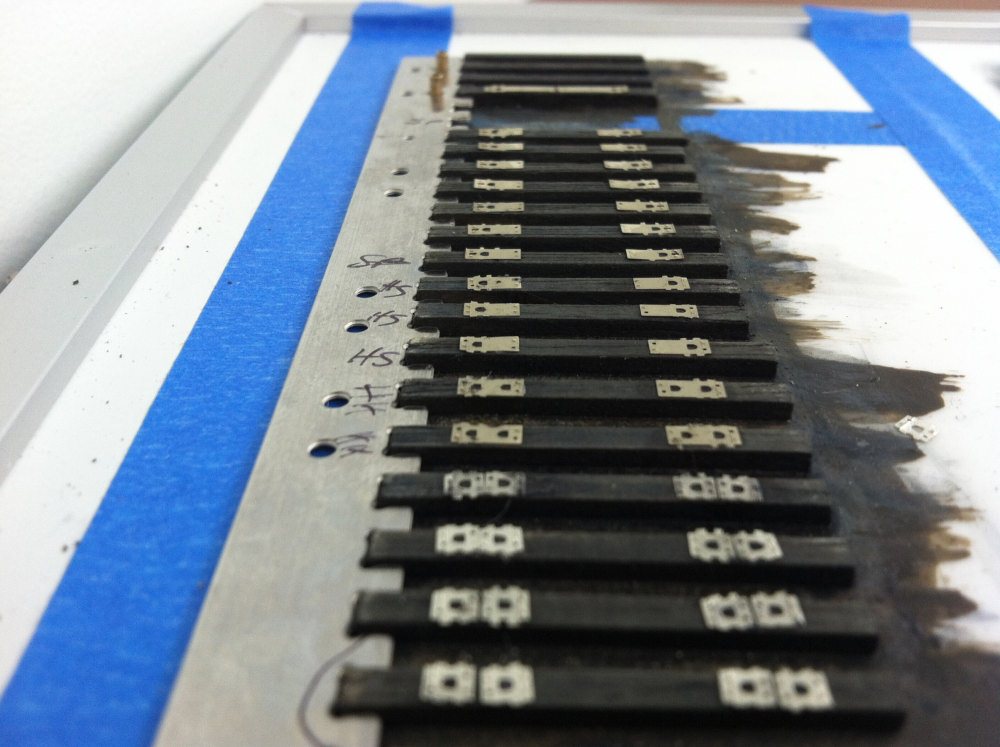

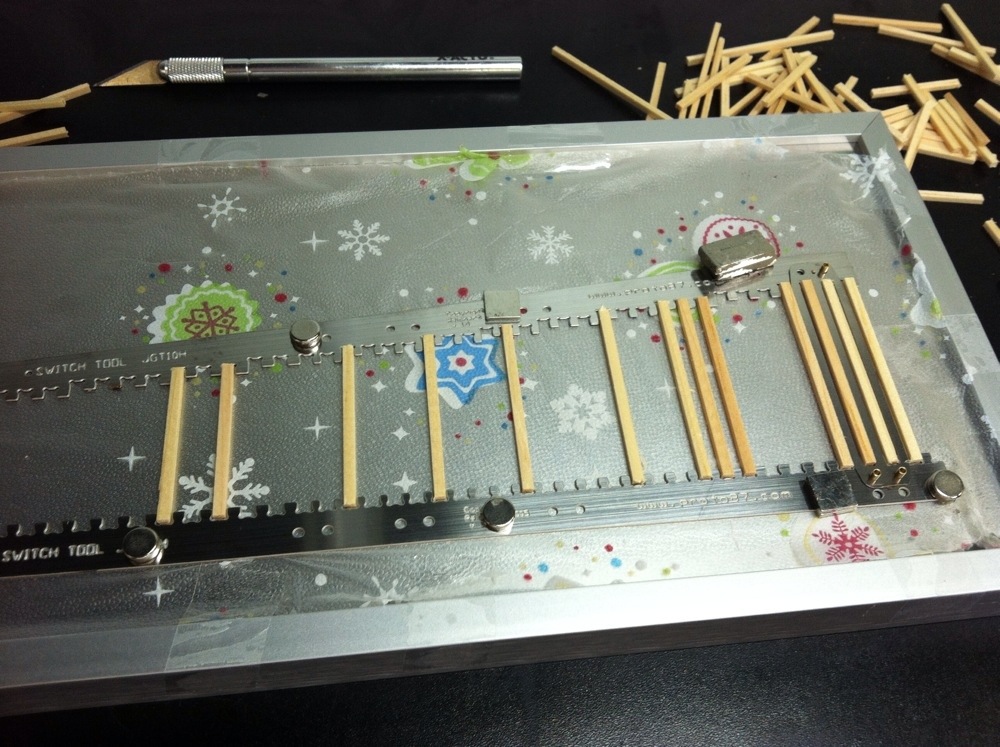

Switch-Works New Gluing Techniques

I have a couple of new techniques for putting together the Ultimate Turnout with the Switch-Works fixture. Glue the ties…

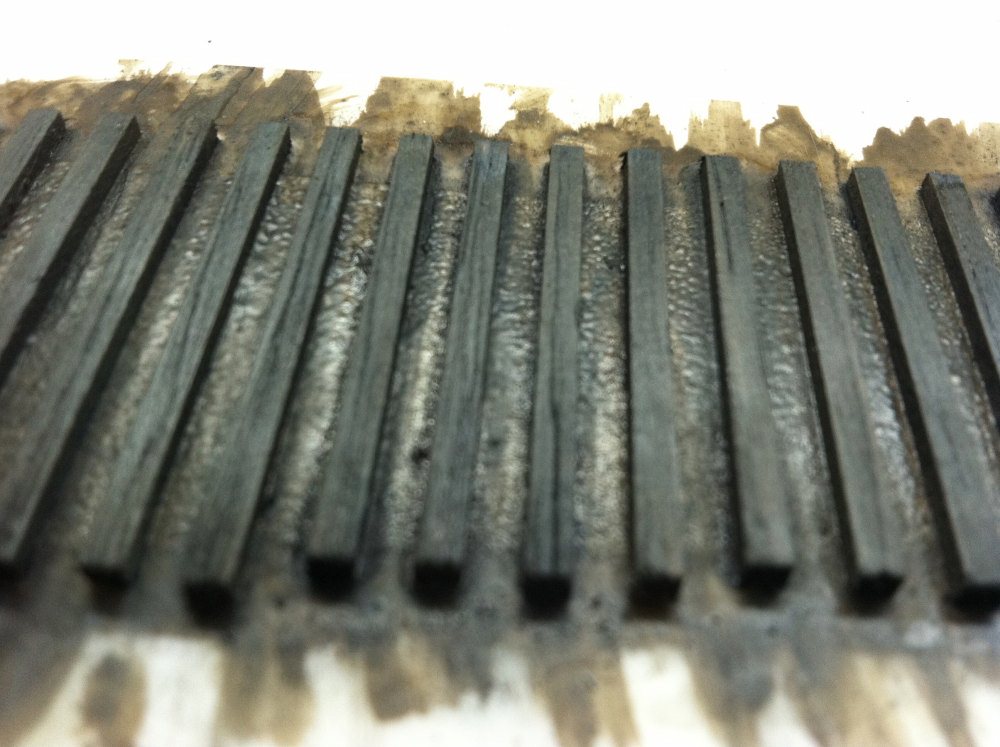

Tie Color and Distress

My first attempt at getting a realistic looking railroad ties. I distressed the ties with an exacto knife, wire brush…

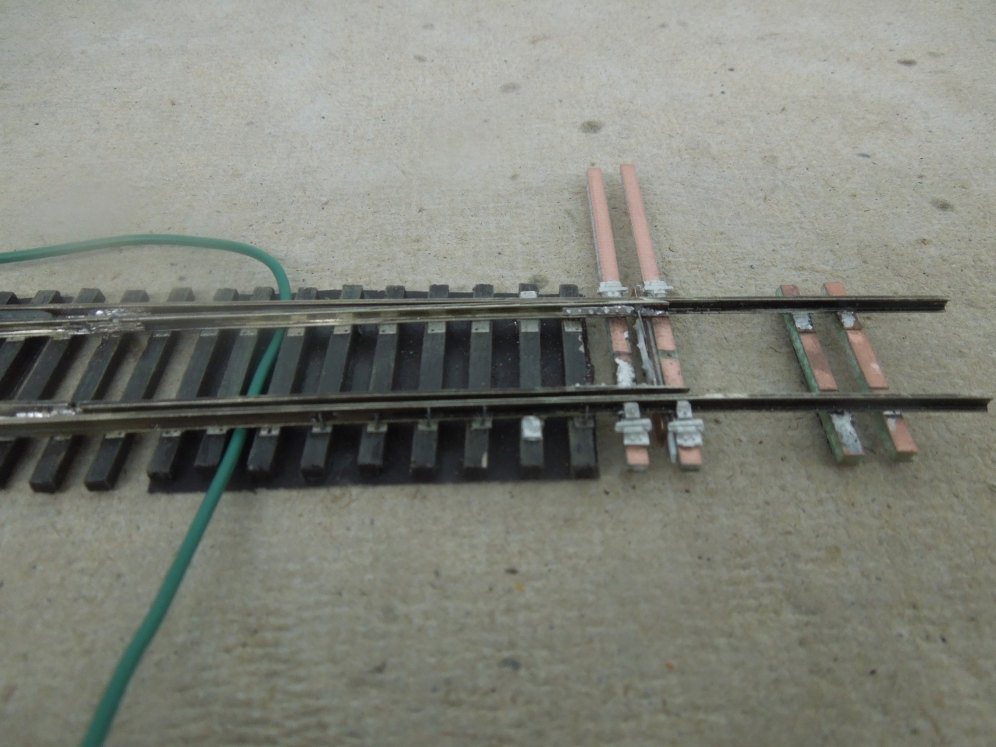

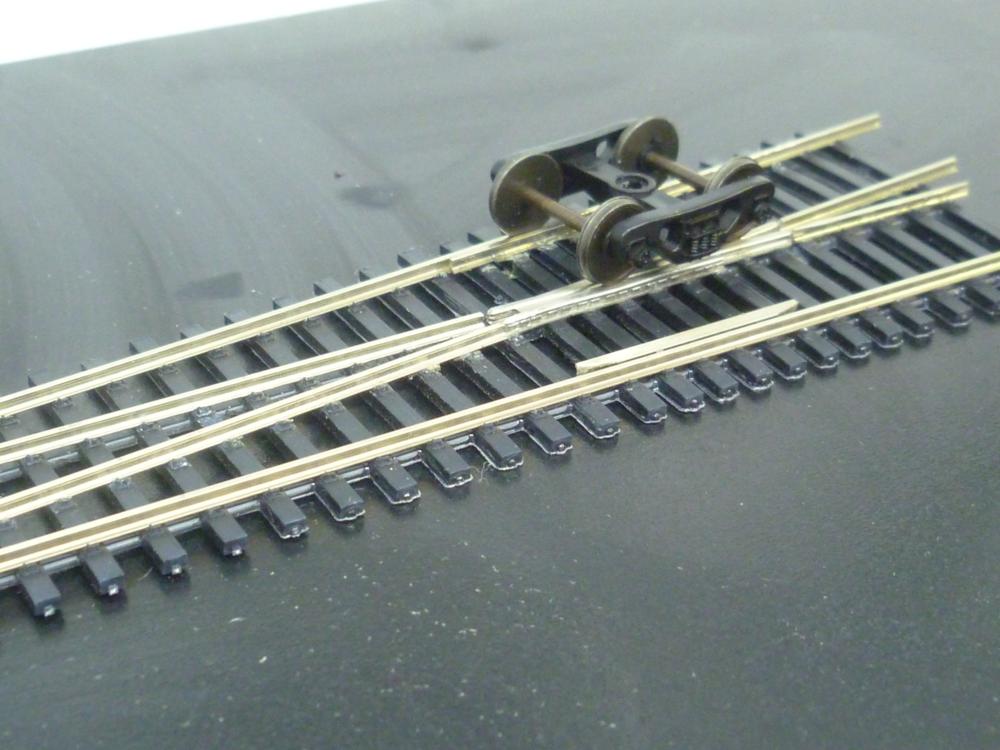

Getting to the Point

I’ve been having trouble making the points of my turnouts fit snugly. Wheels tend to pick the points and cars…

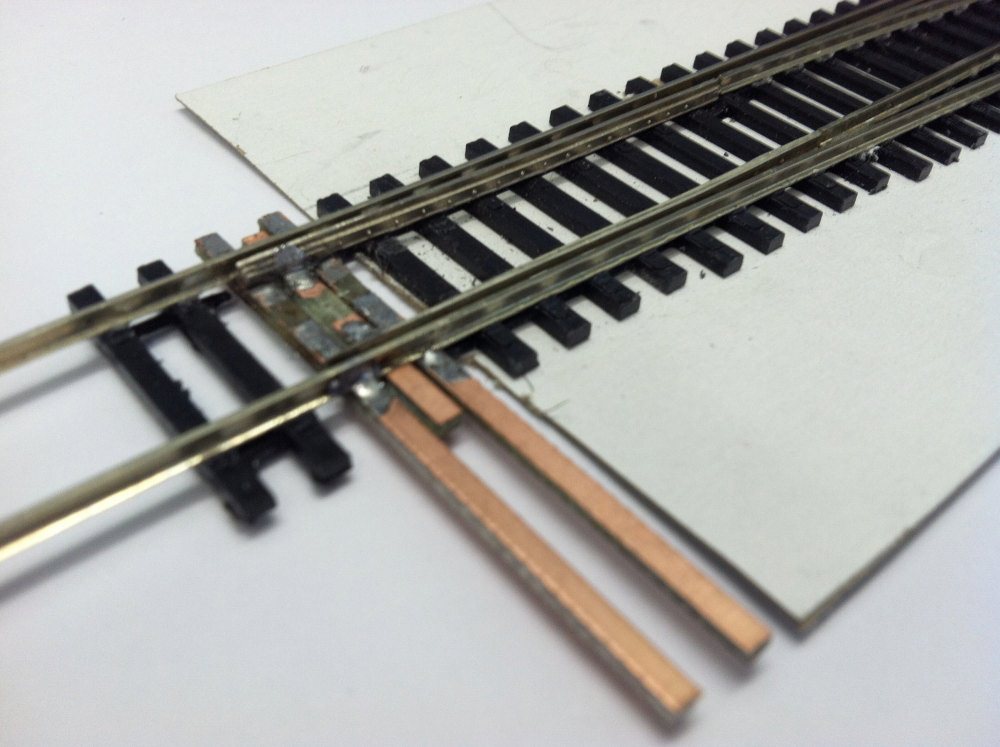

Hybrids and Frankensteins Some Turnout Experiments

I’ve spent the past couple of days experimenting with different turnouts. The victims (shown below) were a Central Valley Ties #9…

Switch-Works – A Second Turnout

February has been a hard month and my second turnout project has been stalled by parts delays, illness, a death,…

Switch-Works Lessons Learned

I’ve finished assembling my first Proto:87 turnout using the Switch-Works Turnout Building fixture. It took about a month and I…

Switch-Works Arrives

My Switch-Works assembly fixture arrived recently and I finally got a chance to get started building some #10 turnouts. After…

Video Update – 2012-11-29

I’ve been mercilessly abusing this Proto:87 Superfine #8 turnout. I’m trying to get as much experience as I can with…

Resurrection – Proto:87 #8 Turnout

I’m not giving up yet! I resurrected the Proto:87 Stores #8 Superfine turnout that I screwed up last week (see: Proto:87…

Peco Headblock Swap

Swapping Headblock ties on Peco Code 83 turnouts. Peco Code 83 turnouts come with the headblock ties extending off of…