Tag: benchwork

Time for a New Desk

When I built my Halland Yard layout, I decided to build my office desk into the closet. It was primarily…

Finishing the Main Deck

I was able finish up cutting the main deck. I cut a filler piece for the east wall, filled a…

Valance Brackets

I painted the top and underside of the valance Polar White. Then installed the triangle brackets that provide the permanent…

Benchwork Continues – Into the Closet

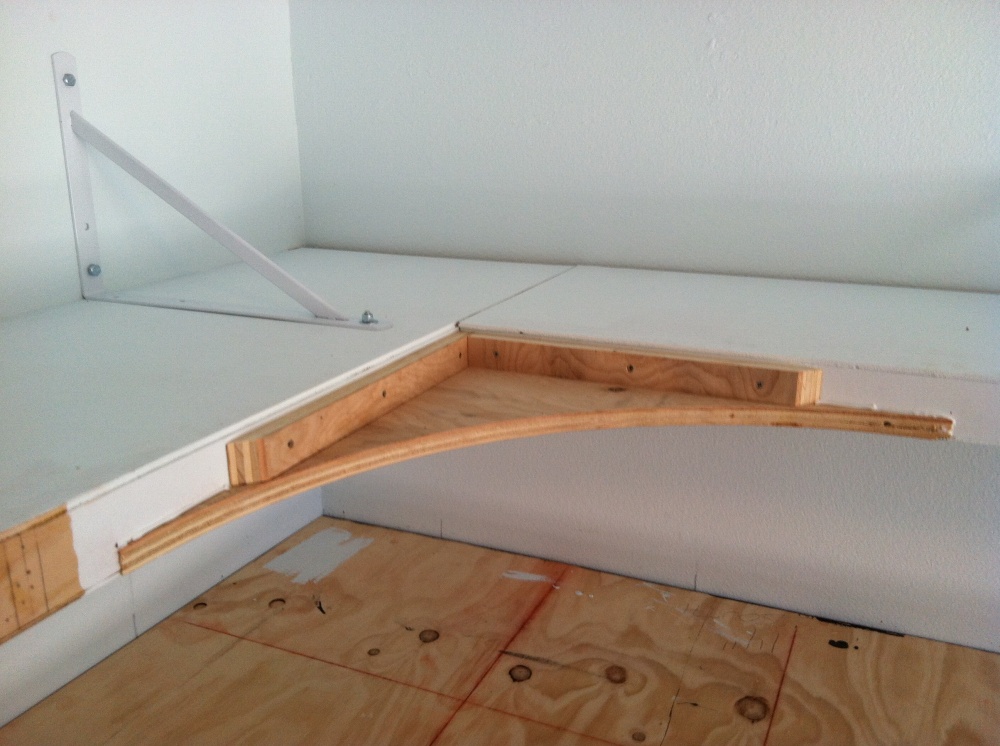

More benchwork today. I started with a tricky section that would be the sub-roadbed where the main layout enters the…

Touch up and Valance 4-16-2012

A couple extra hours of work allowed me to do a little touch up and finish out the valance frame….

Construction Marathon 4-15-2012

A nice day and generous parents led me to a construction marathon this afternoon. I spent a total of 8…

L Girder

Primed FJ Pine L Girder for valance. This primed pine is 30% cheaper than Home Depot’s common pine and it’s…

Progress 4-2-12

Progress has really been stifled by rain, sick kids, injury, illness and RAIN. And did I mention rain. So in between the…

Brackets In Now Take Them Out

Lowering the Bench I got all of the brackets and ledger boards installed and then decided to listen to some…

Shelf Bracket Benchwork 1

Progress I started benchwork today. I’m using angle brackets from Home Depot; 16″ brackets along the east wall and 12″…